Lubricant filling machine: The Selection Guide

Aug 13, 2024|

Aug 13, 2024| View:148

View:148Product Type: Consider the type of lubricants you will be filling. Different machines are designed for various viscosities and types of fluids.

Volume Range: Determine the range of volumes you need to fill, from small bottles to large containers.

Filling Accuracy: High precision is essential, especially for lubricants where the quantity can affect performance.

Repeatability: The Lubricant filling machine should consistently deliver the same fill volume across multiple cycles.

Filling Speed: Assess the speed of the filling process and how it aligns with your production requirements.

Operational Efficiency: Look for machines with minimal downtime and easy maintenance routines.

Adaptability: The Lubricant filling machine should be adaptable to different container sizes and shapes.

Upgradeability: Consider whether the machine can be upgraded to meet future production needs.

Contact Materials: Ensure that the materials in contact with the lubricant are compatible to prevent contamination or degradation.

Semi-Automatic vs. Fully Automatic: Decide based on your production scale and labor availability.

Control Systems: Modern machines often come with advanced control systems for better process management.

Safety Shields: Ensure the Lubricant filling machine has safety shields to protect operators from moving parts.

Emergency Stop: A readily accessible emergency stop function is a must.

Ease of Cleaning: The machine should be easy to clean and sanitize to meet hygiene standards.

Drainage System: A proper drainage system to avoid residue buildup is essential.

Waste Management: Consider machines that minimize spillage and have efficient waste management systems.

Energy Efficiency: Opt for Lubricant filling machine that consume less energy to reduce environmental impact.

Initial Investment: Compare the costs of different machines within the required specifications.

Operational Costs: Consider the long-term costs, including energy consumption, maintenance, and replacement parts.

Warranty: Check the warranty terms and what they cover.

Technical Support: Ensure the Lubricant filling machine manufacturer provides reliable technical support and spare parts.

Industry Standards: The machine should comply with relevant industry standards and regulations.

Certifications: Look for certifications that guarantee quality and safety.

Operator Comfort: The design should take into account the comfort of the operators during long shifts.

Control Panel Accessibility: The control panel should be easily accessible and user-friendly.

Future Growth: Consider whether the Lubricant filling machine can handle increased production volumes as your business grows.

Operator Training: Ensure that the manufacturer provides training for operators to use the machine safely and efficiently.

Maintenance Training: Training for routine maintenance and troubleshooting is also beneficial.

Customer Feedback: Look for reviews and ask for references to gauge the machine's performance and reliability.

Compatibility: Check if the Lubricant filling machine can integrate seamlessly with your existing production line and packaging equipment.

Latest Technology: Opt for machines that incorporate the latest technology for improved performance and reduced operational challenges.

Special Requirements: If you have specific needs, such as a particular type of nozzle or filling technique, ensure the machine can accommodate these.

Demonstration: If possible, request a demonstration or trial run with your product to see the machine in action.

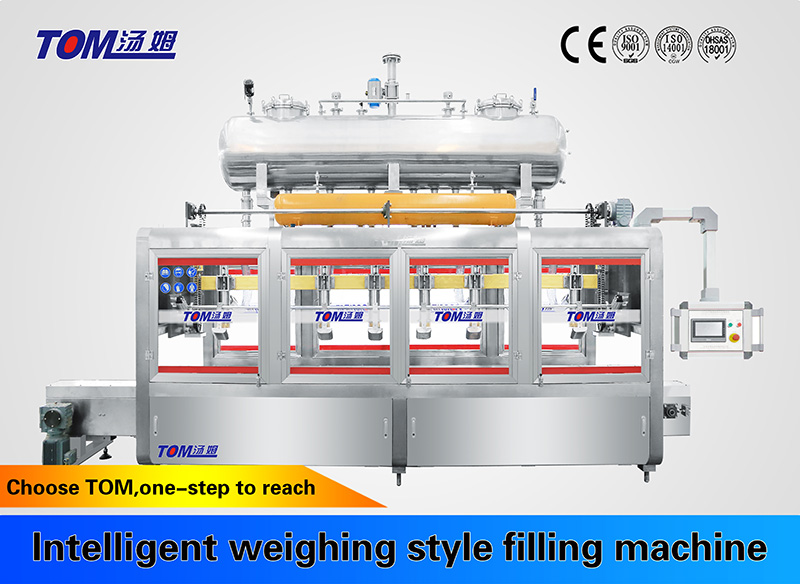

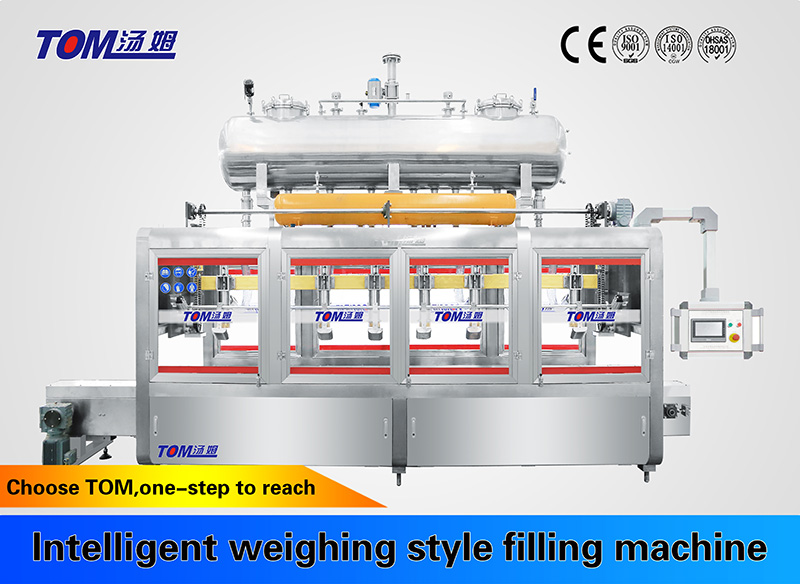

Intelligent weighing style lubricant filling machine

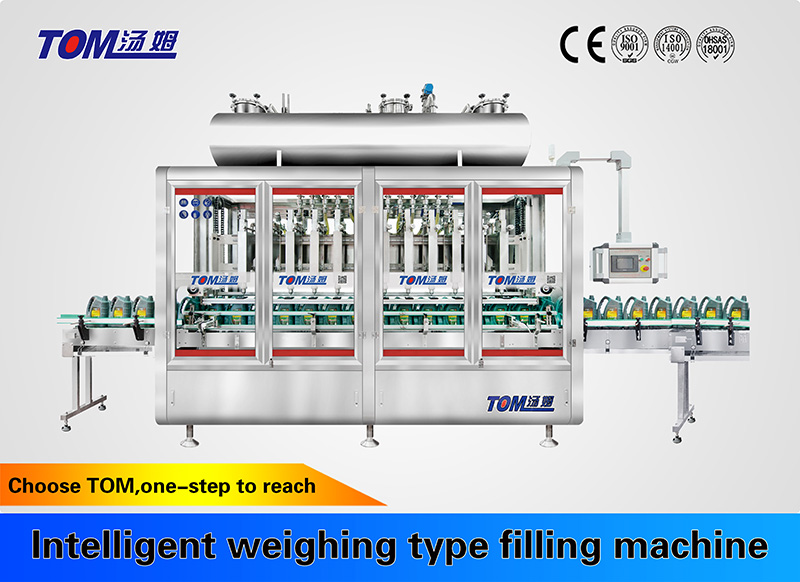

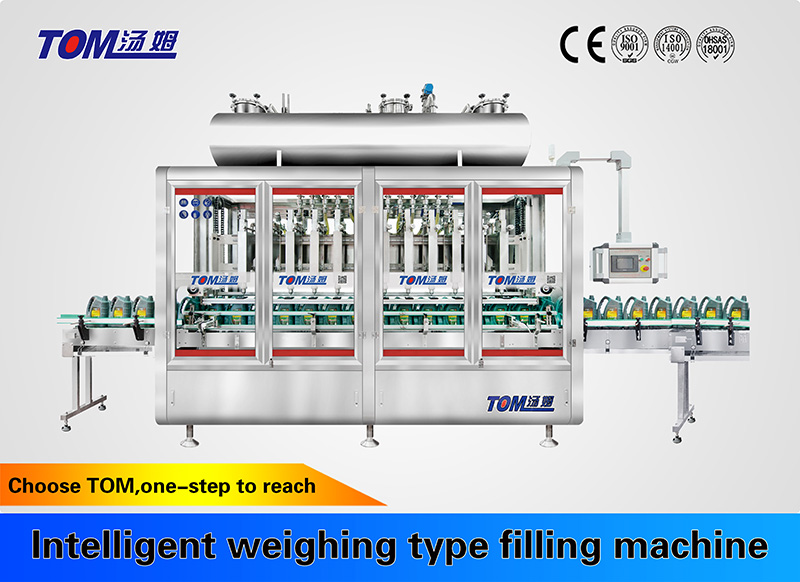

Intelligent weighing type lubricant filling machine

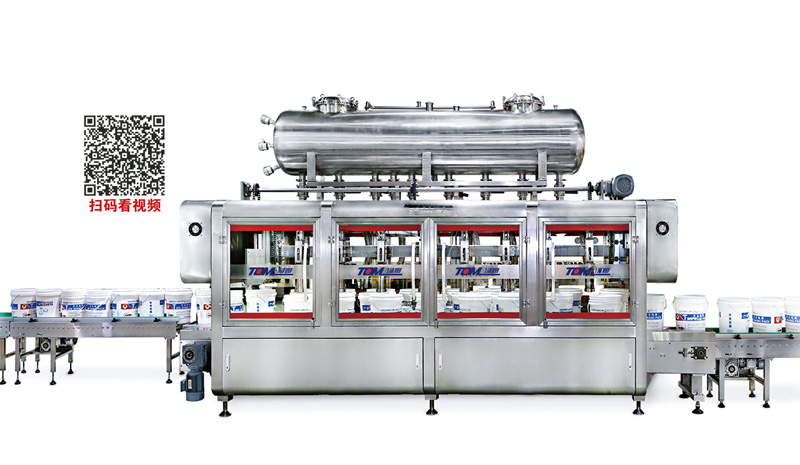

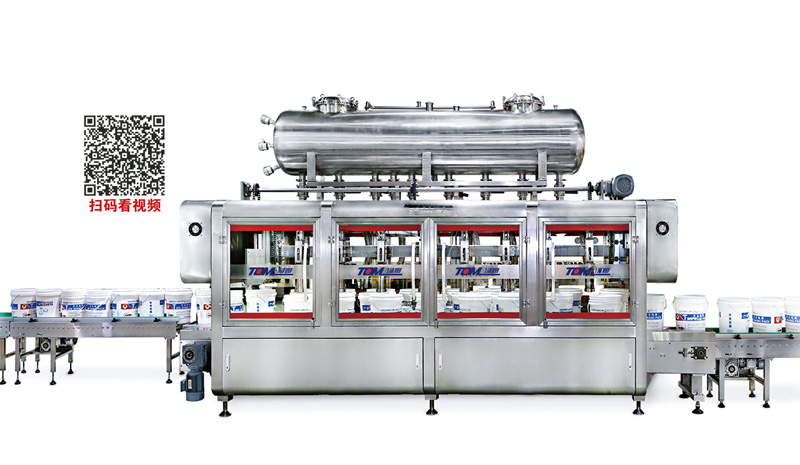

Mode DGP-CZ-2B weighing lubricant filling machine

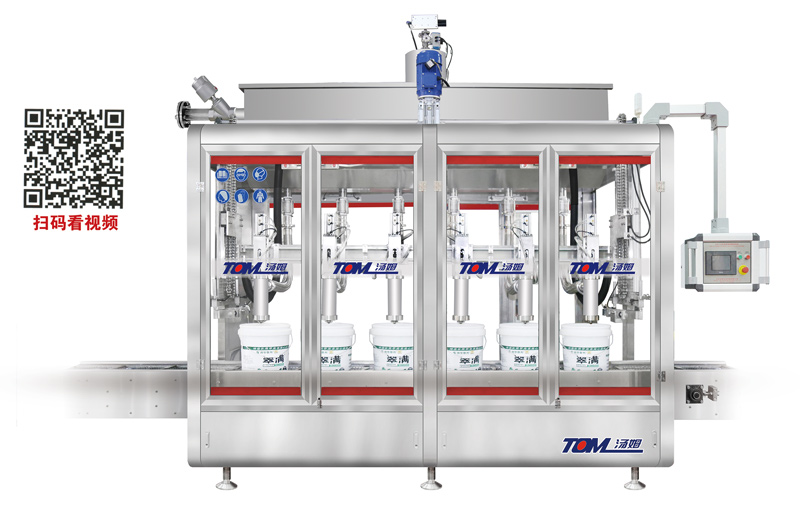

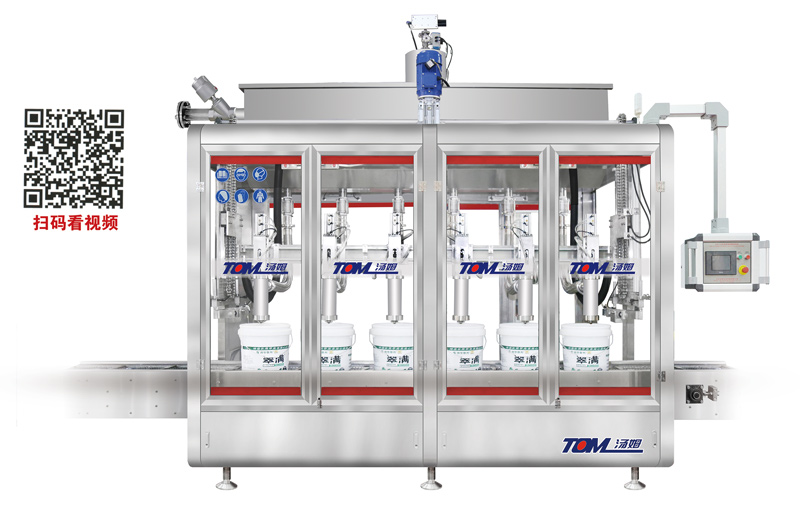

DGP-CZ-200R weighing style filling machine for barrels suitable for lubricant

DGP-SCZ-12 automatic weighing type lubricant filling machine

Automatic lubricant /coatings pail filling machine

Lubricant filling capping monoblock

lubricant pail filliig machine